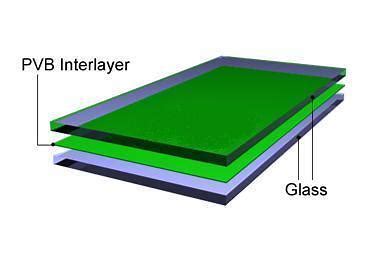

Moisture in PVB for safety glass

Plastic foils made of polyvinyl butyral (PVB) are required to produce laminated safety glass using for auto and building industry.

Adhesion PVB Plastic foils works best when the moisture is between 0.4% and 0.65%.

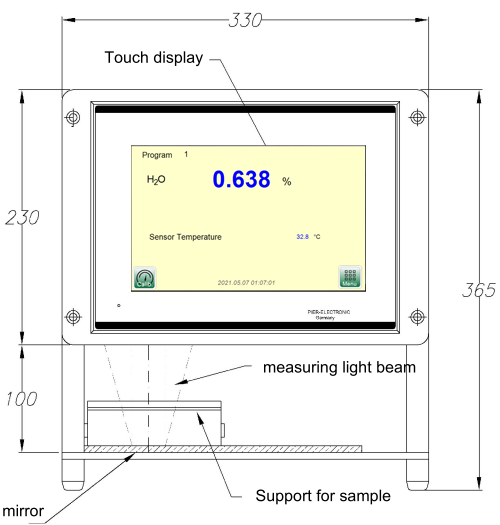

Our Reflection Photometer (RMK-9T) can online, non-contact control and monitor the water content in plastic foils during the production, storage, transportation, and lamination of the PVB safety glass.

| Measurement range: | 0–1% moisture |

| additionally: | 0–2 mm thickness |

| Accuracy: | +/- 0.01% moisture / 0.02 mm thickness |

| Reproducibility: | 0.005% |

| T90: | 1 sec. |

Technical Data

| Display | type TFT with auto. Lighting off |

| | Size 25.7 cm (10.1″) |

| | Resolution 1280 x 800 pixels, WVGA |

| | Touchscreen PCAP, capacitive |

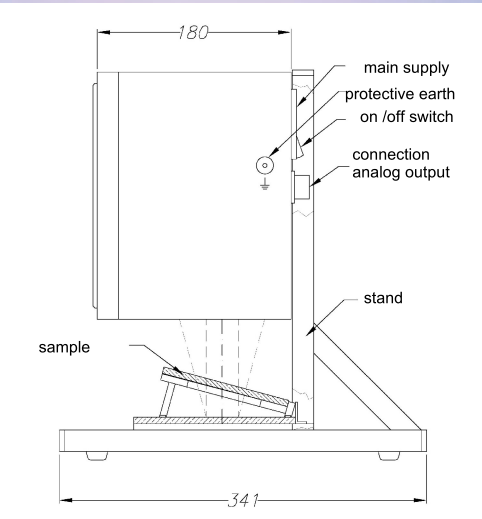

| Processor | architecture ARM Cortex A9 |

| | Clock frequency 800 MHz |

| | RAM 1 GB/ Flash 1 GB/ Retain 64 KB |

| Outputs | Digital input 4 x 24 VDC, 2.25 mA, resolution 12 Bit, |

| | Digital output 4 x 24 VDC, transistor, 0.5 A |

| | Watchdog relay output 1 x +24 VDC |

| Software | Software like IEC 61131 |

| | web-server |

| | with up to 100 programs |

| | Scope-diagnose and more |